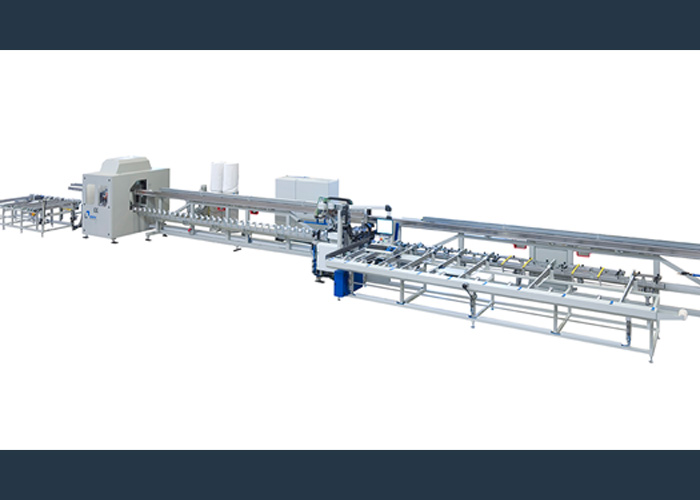

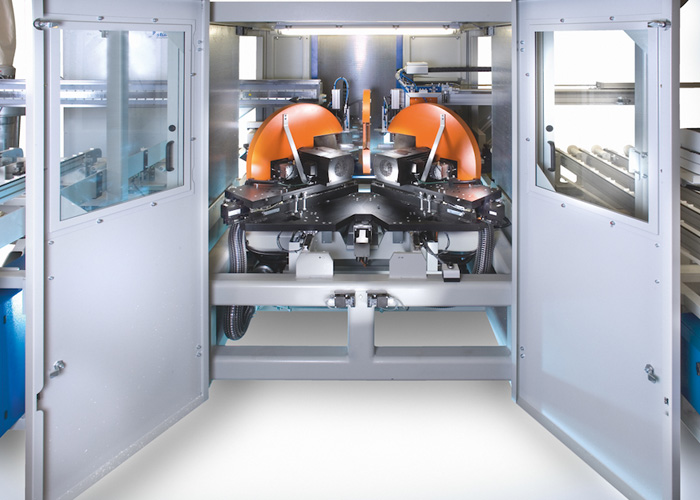

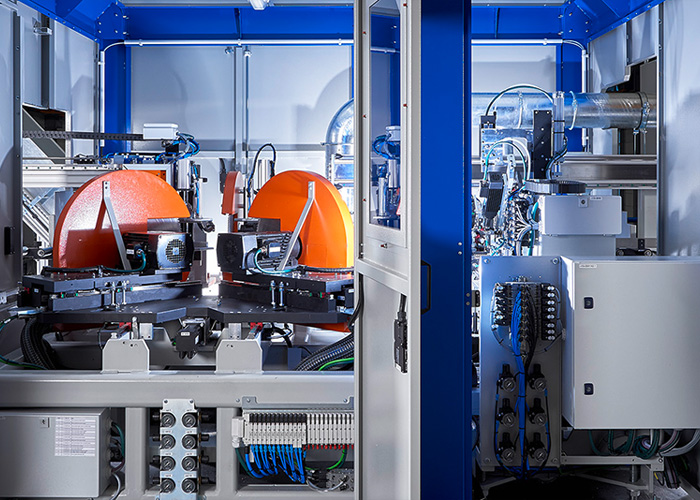

Flexcenter-260-PPX

The Advantages

- Complete machining of PVC window and front door profiles with a production output of 250 up to 300 window units per shift

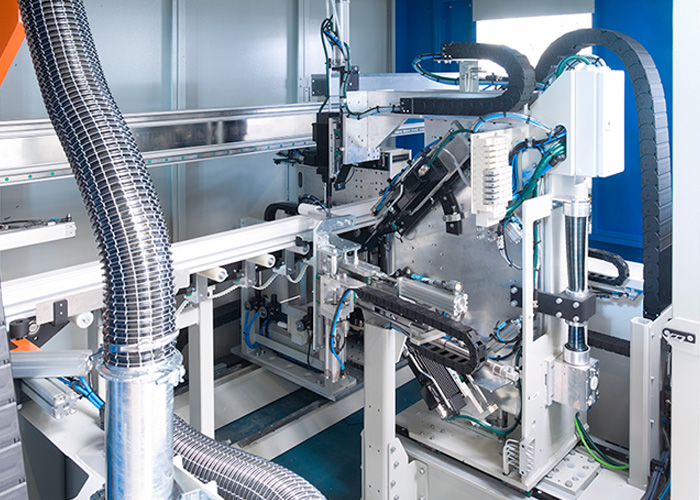

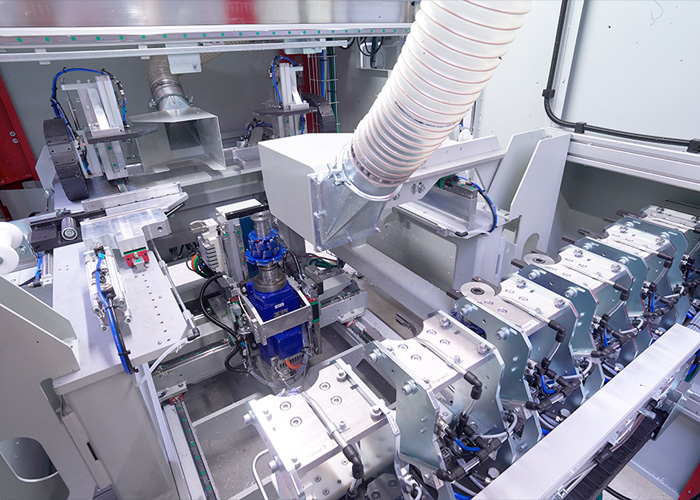

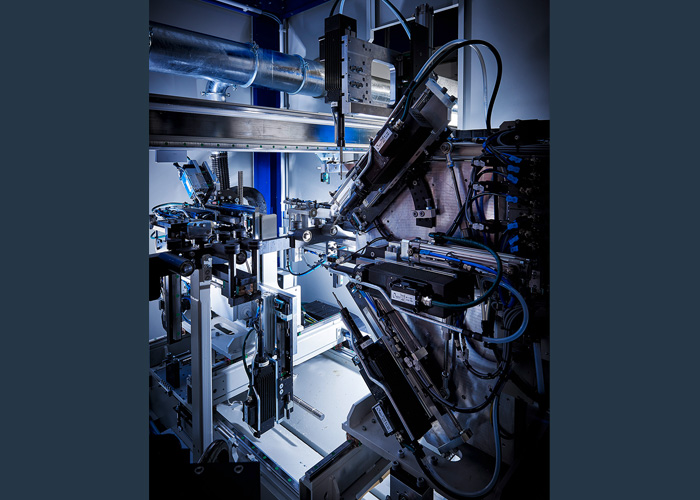

- Parallel processing: Shorter processing cycles by decoupling the machining operations on the bar

- Freely configurable system through consistent modularity

- Ease of use and data maintenance

- Freely programmable machining data

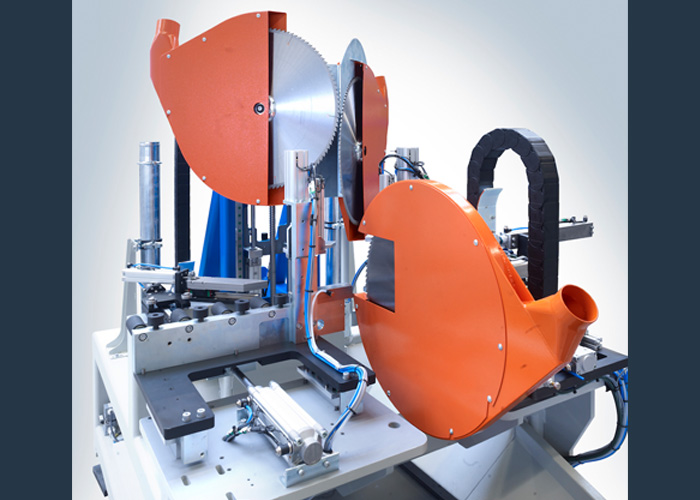

- Profile bar systems PVC / PVC steel-reinforced composites

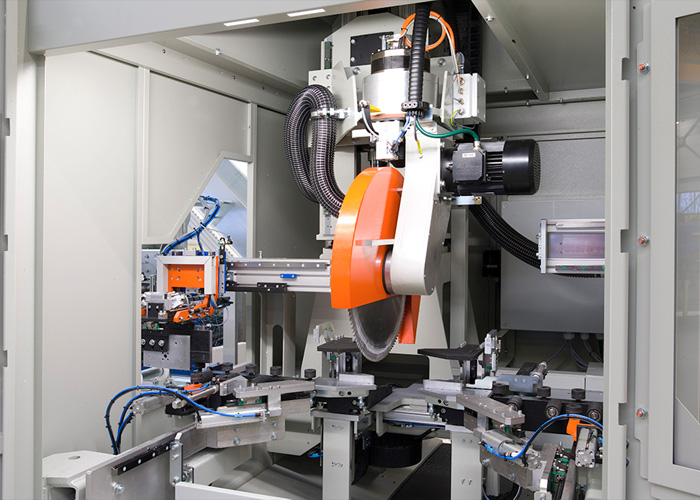

- Versatile additional functions such as variable saw, inline printer, seal undercutting and transom milling station with changer, automatic clamping part setting and screwing station and stacking system possible

The Advantages

- Complete machining of PVC window and front door profiles with a production output of 250 up to 300 window units per shift

- Parallel processing: Shorter processing cycles by decoupling the machining operations on the bar

- Freely configurable system through consistent modularity

- Ease of use and data maintenance

- Freely programmable machining data

- Profile bar systems PVC / PVC steel-reinforced composites

-

Versatile additional functions such as variable saw, inline printer, seal undercutting and transom milling station with changer, automatic clamping part setting and screwing station and stacking system possible

Technical Data

Storage magazine

| 12 places |

Profile bar length min |

650 mm |

Profile bar length max |

6500 mm |

Cutting length min |

326 mm |

Cutting length max |

4006 mm (optional 6006 mm) |

Profile face width |

130 mm |

|

| Profile depth | 120 mm (optionally 180 mm) |