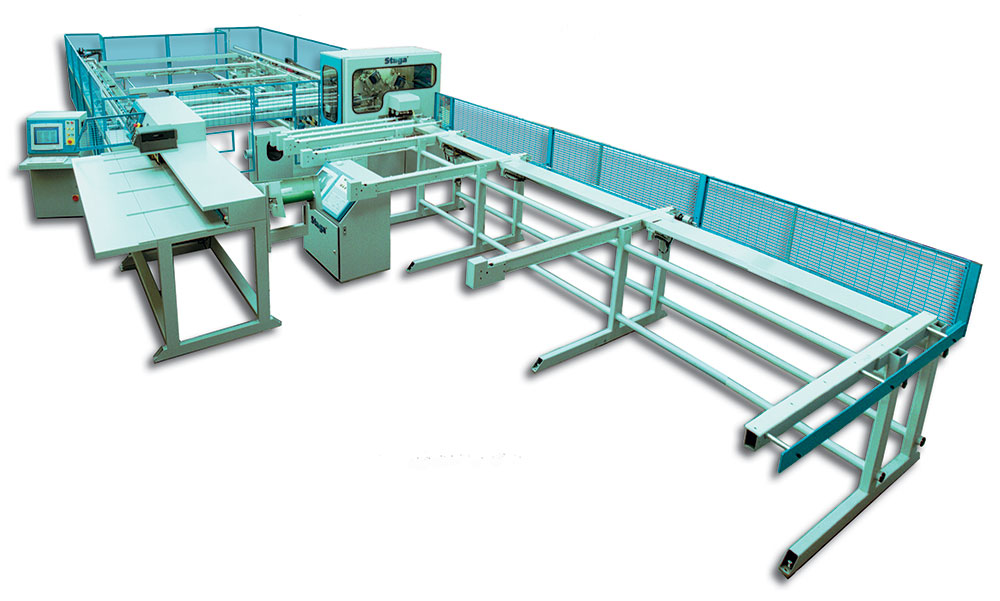

Stuga are having much success with an upgraded version of this popular sawing & machining centre when stocks are available. These machines are upgraded from old Stuga machines when they become redundant or surplus to requirement for any reason to a version very similar to the ZX3 but now including the tru-loc gripper system.

Stuga built 76 Flowline sawing & machining centres between the end of 1999 and the middle of 2006. These machines have been very successful and the mainstay of production for numerous well known names in the uPVC fabrication industry.

The Flowline was superseded in 2006 by the ZX3 centre which has many new features and is much quicker. Electronics, software and control systems have evolved at a fast pace in recent years and the ZX3 is designed to keep up with these changes. The ZX3 has itself now been superseded by the ZX5-E.

Older models of the Flowline occasionally come to Stuga through the trade-in route or are purchased from fabricators that are downsizing or going out of business.

These machines are totally rebuilt in the factory where they were originally built in Norfolk and sold as ‘like new’ with a full 12 months parts and labour warranty. The Flowline can be rebuilt to the same output specification as the original Flowline of 500 to 550 windows per week or to the latest output specification of the ZX3 at 600 to 700 windows per week with ‘double-plunge’ technology for fast production of trickle vents and doors. Either version has the latest software, electronics and control systems the same as used on the very latest leading edge centres sold today.

Machines are rebuilt to order and offered only subject to the availability of donor machines. The lead time for one of these machines is always the same as for a new machine as this is a total rebuild project.

The price advantage over a new machine is significant as there is considerable value in the basic chassis and general metalwork but these machines are not cheap.